You can learn the recent information of Shijing.

Tile cutter manufacturers play a pivotal role in the construction and renovation industry by providing essential tools for cutting and shaping ceramic, porcelain, and other types of tiles. Their expertise and innovation shape the standards for precision, durability, and efficiency in tile cutting. In this article, we'll explore how tile cutter manufacturers set the standard in the industry through their commitment to quality, innovation, and customer satisfaction.

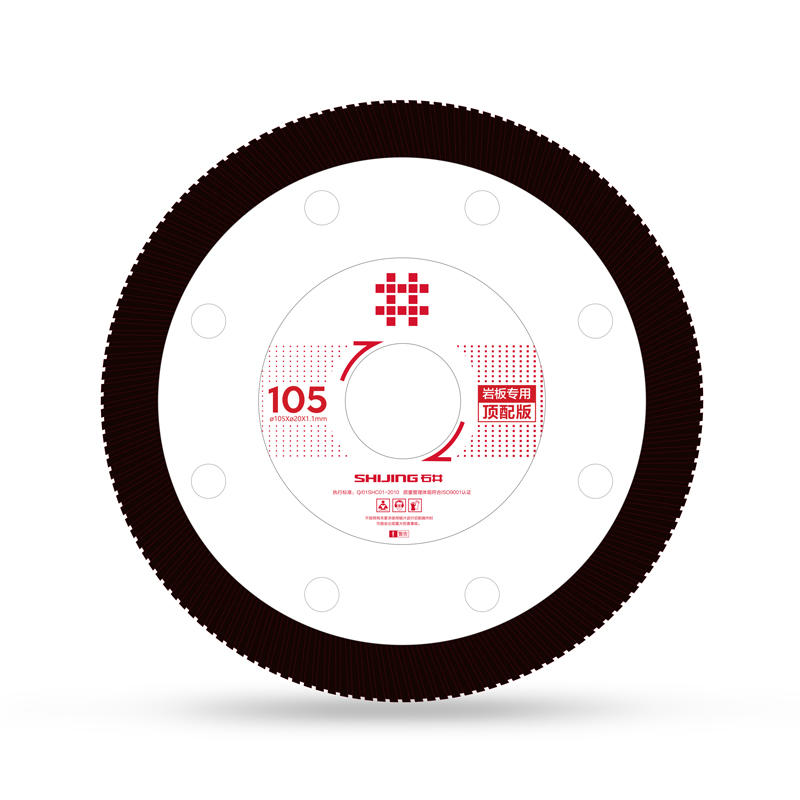

At the heart of every tile cutter is precision engineering, and manufacturers excel in this aspect. They employ advanced technologies and meticulous craftsmanship to design and produce tile cutters that deliver accurate and clean cuts consistently. From the cutting wheel to the guide rails, every component is engineered to exacting standards, ensuring that professionals and DIY enthusiasts

Tile cutter manufacturers prioritize the use of high-quality materials in their products to ensure durability and longevity. They carefully select materials such as hardened steel for cutting wheels, aluminum for frames, and robust plastics for handles and grips. By using premium materials, manufacturers guarantee that their tile cutters can withstand the rigors of daily use on construction sites or in workshops without compromising performance or reliability.

Innovation is the driving force behind the evolution of tile cutter technology, and manufacturers are at the forefront of this endeavor. They invest in research and development to explore new cutting mechanisms, ergonomic designs, and user-friendly features that enhance efficiency and productivity. Whether it's introducing laser-guided cutting systems or developing compact and portable tile cutters, manufacturers strive to push the boundaries of what's possible in tile cutting.

Tile cutter manufacturers closely monitor market trends and customer feedback to adapt their products to meet evolving needs and preferences. They offer a diverse range of tile cutters, from manual score-and-snap models to electric wet saws, to cater to different applications and user requirements. Manufacturers also provide accessories and attachments, such as angle guides and extension tables, to enhance the versatility and functionality of their tile cutters, ensuring that they remain relevant in a dynamic market landscape.

Before reaching the hands of consumers, tile cutters undergo rigorous testing and quality assurance measures to ensure their performance and reliability. Manufacturers subject their products to various tests, including cutting accuracy, blade durability, and ergonomic comfort, to verify that they meet or exceed industry standards. This commitment to quality assurance instills confidence in customers, assuring them that they're investing in a tool that will deliver consistent results and withstand the demands of their projects.

Tile cutter manufacturers understand that proper training and support are essential for users to the potential of their products. They provide comprehensive user manuals, instructional videos, and online resources to guide customers through the assembly, operation, and maintenance of their tile cutters. Additionally, manufacturers offer technical support and customer service to address any questions or concerns that users may have, ensuring a positive experience throughout the lifespan of the product.

In today's environmentally conscious world, tile cutter manufacturers are increasingly prioritizing sustainability and eco-friendliness in their operations. They implement eco-friendly manufacturing processes, such as recycling scrap materials and reducing energy consumption, to minimize their environmental footprint. Manufacturers also develop tile cutters with eco-friendly features, such as water-saving designs and low-emission motors, to promote sustainability in the construction industry and reduce the impact on the planet.

Tile cutter manufacturers collaborate with industry professionals, including tile installers, contractors, and architects, to gain insights into real-world applications and challenges. They actively seek feedback from professionals to identify areas for improvement and innovation in their products. By partnering with industry experts, manufacturers ensure that their tile cutters are designed and engineered to meet the demanding requirements of professionals working in the field.

Above all, tile cutter manufacturers are committed to customer satisfaction. They strive to deliver products that exceed customer expectations in terms of performance, reliability, and value. Manufacturers stand behind their tile cutters with warranties and guarantees, offering peace of mind to customers and reinforcing their confidence in the quality of the product. By prioritizing customer satisfaction, manufacturers build long-lasting relationships with their customers and establish themselves in the industry.

In conclusion, tile cutter manufacturers set the standard in the industry through their dedication to precision engineering, quality materials, continuous innovation, adaptability to market needs, rigorous testing and quality assurance, training and support, environmental responsibility, collaboration with industry professionals, and commitment to customer satisfaction. Their tireless pursuit of excellence ensures that professionals and DIY enthusiasts alike have access to the tools they need to achieve outstanding results in tile cutting applications.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

-4.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)