You can learn the recent information of Shijing.

Wholesale automatic copper tube cutting machine Tools Factory

In the intricate world of tile cutting, the precision and efficiency of the process hinge on one critical factor: Cutting Tools. These indispensable implements are the backbone of any successful tiling project, and their design holds the key to achieving flawless results. This article delves into the mechanical design aspects of Cutting Tools, examining how blade shape, serrated design, and cooling systems contribute to the performance of these indispensable tools.

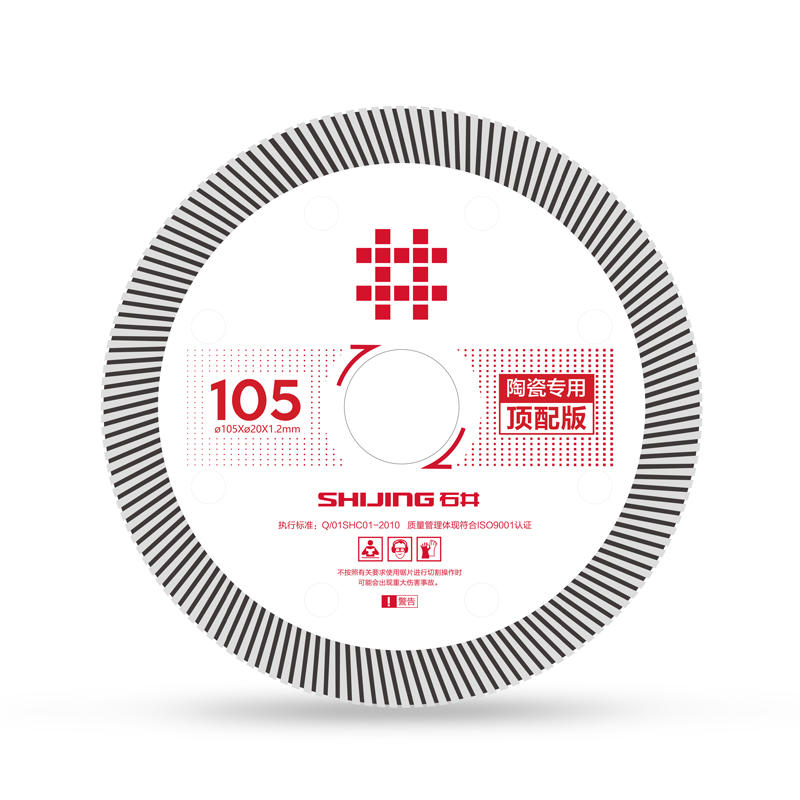

The shape of a Cutting Tool's blade is not just a matter of aesthetics; it is a crucial factor in determining the tool's cutting efficiency and precision. Straight-edged blades are ideal for clean, straight cuts, while wave-patterned designs excel in scoring and breaking tiles without the risk of chipping. Circular blades, on the other hand, are for intricate designs and curved cuts, showcasing the versatility of Cutting Tools in various applications.

Manufacturers of Cutting Tools are constantly innovating to create blades that cater to the specific needs of different materials and cutting styles. For instance, a wave-shaped serrated blade on a Cutting Tool can handle the brittle nature of porcelain tiles, while a straight, fine-toothed blade is more suited for the smooth cuts required in natural stone.

One of the innovative features of modern Cutting Tools is the incorporation of cooling systems. These systems play a dual role in the cutting process: they reduce the heat generated during cutting, thereby minimizing the risk of tile damage, and they also prolong the life of the Cutting Tools by preventing rapid wear.

External cooling systems, such as water sprays, are commonly used with tile Cutting Tools to keep the cutting area cool. This method is particularly effective in preventing thermal shock, which can cause tiles to crack or break. Internal cooling channels within the Cutting Tools are another sophisticated approach, directing coolant directly to the cutting edge for performance.

The mechanical design of Cutting Tools is evolving, with a focus on materials science and ergonomics. Lightweight yet robust materials are being used to manufacture Cutting Tools that are easier to handle while maintaining their durability. Additionally, the integration of smart cooling systems, which adjust the flow of coolant based on the cutting conditions, is on the horizon.

In the competitive landscape of the tile industry, Cutting Tools that offer a combination of precision, efficiency, and durability are in high demand. The mechanical design of these tools is paramount, as it directly impacts the quality of the final product. From the blade shape that determines the cut's accuracy to the cooling systems that ensure the tool's longevity, every aspect of Cutting Tools design is critical.

As the tile-cutting industry continues to advance, the role of Cutting Tools becomes increasingly significant. These tools are not just simple implements; they are the result of meticulous engineering and design, tailored to meet the specific demands of the trade. The future looks promising, with innovations in Cutting Tools design set to transform the way we approach tile cutting, making it faster, more precise, and more efficient than ever before.

In conclusion, the art of Cutting Tools design is a delicate balance of form and function, where every detail contributes to the overall performance. As we continue to push the boundaries of what's possible with Cutting Tools, one thing is certain: the pursuit of ion in tile cutting will drive the industry forward, ensuring that Cutting Tools remain at the forefront of innovation.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-3.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)