You can learn the recent information of Shijing.

In the ever-evolving world of construction and interior design, precision and efficiency are of utmost importance. Tile cutter manufacturers play a pivotal role in ensuring that tiles are accurately cut to fit various spaces with precision. With advancements in technology, these manufacturers are redefining precision, and elevating the standards of tile cutting processes. This article explores how tile cutter manufacturers are revolutionizing the market by incorporating cutting-edge technology and emphasizing precision.

Evolution of Tile Cutter Manufacturing

Tile cutter manufacturing has come a long way since its inception. Earlier, manual tile cutters were prevalent, requiring significant physical effort and resulting in inconsistent cuts. However, with technological advancements, tile cutter manufacturers have introduced innovative electric and manual tile cutters that enhance precision while reducing the effort required.

Incorporating Advanced Technology

Tile cutter manufacturers are embracing cutting-edge technology to redefine precision. The incorporation of laser guide systems has revolutionized the accuracy of tile cutting. These laser guides project a thin beam onto the tile, providing a precise cutting line, and ensuring that every cut is flawless. This advanced technology is enhancing the efficiency and precision of tile cutting processes, reducing waste, and increasing productivity.

Automatic and Adjustable Features

Manufacturers are incorporating automatic and adjustable features in tile cutters to enhance precision. Automatic cutting machines come equipped with advanced sensors that detect the dimensions of the tile and automatically set the cutting parameters accordingly. This eliminates the risk of human error and ensures precise cuts every time. Additionally, adjustable features such as adjustable cutting angles and cutting depths allow for versatile tile cutting, enabling seamless installation even in complex spaces.

High-Quality Materials and Durability

Tile cutter manufacturers are focusing on using high-quality materials to ensure durability and long-lasting performance. Cutting wheels made from tungsten carbide, a robust and wear-resistant material, are being incorporated. This ensures that the cutting wheels maintain their sharpness and precision even after prolonged use. The use of high-quality materials enhances the reliability of tile cutters, reducing the need for frequent maintenance or replacement.

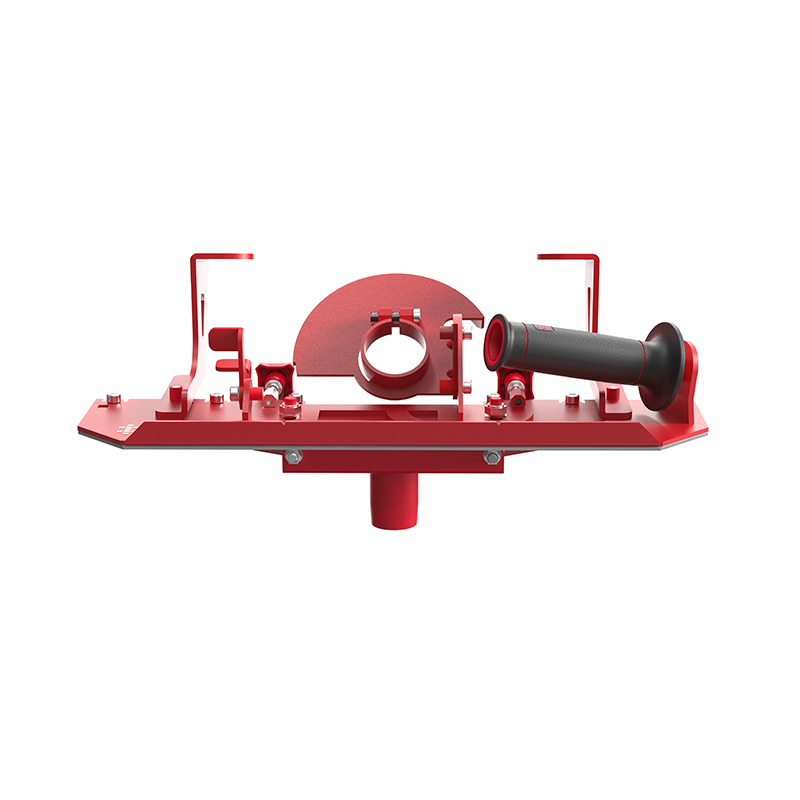

Ergonomic Design for Enhanced Precision

Tile cutters are being designed with ergonomics in mind. Manufacturers are paying attention to the comfort and ease of use for operators, as these factors directly impact precision. Ergonomic handles and grips, along with adjustable working heights, reduce operator fatigue, enabling them to maintain accuracy throughout the tile cutting process. Enhanced precision is achieved when operators can comfortably maneuver the tile cutter, resulting in refined cutting techniques.

User-Friendly Interfaces

Tile cutter manufacturers are investing in intuitive and user-friendly interfaces to enhance precision. Digital displays and touch screens provide operators with real-time information, enabling them to accurately monitor cutting parameters, including cutting speed and depth. These interfaces also allow for customization based on specific tile materials and sizes, catering to various cutting requirements. User-friendly interfaces contribute significantly to precision by ensuring that operators have complete control over the cutting process.

Incorporating Safety Features

Maintaining a safe working environment is crucial in any manufacturing process. Tile cutter manufacturers are integrating safety features into their products to safeguard operators and further enhance precision. Safety guards, anti-slip surfaces, and emergency stop buttons are some of the safety measures being incorporated. These features not only reduce the risk of accidents but also instill confidence in operators, enabling them to focus on achieving precise cuts.

Conclusion

As the construction and interior design industries continue to evolve, tile cutter manufacturers are redefining precision through technological advancements and innovative design. Incorporating advanced laser guide systems, automatic and adjustable features, high-quality materials, ergonomics, user-friendly interfaces, and safety features are some of the ways these manufacturers are revolutionizing the market. With tile cutter manufacturers consistently pushing the boundaries of precision, the future of precise tile cutting looks promising, enabling flawless installations for a wide range of projects.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-1.jpg)

.jpg)

.jpg)

.jpg)

.jpg)