You can learn the recent information of Shijing.

OEM Manual Tile Cutting saw Factory

In the world of tiling, manual tile cutting remains a key technique for both professional tilers and DIY enthusiasts. Known for its precision, simplicity, and cost-effectiveness, manual tile cutting has come a long way with innovative developments enhancing its usability and effectiveness. These improvements are not only increasing the popularity of manual tile cutting tools but also pushing the boundaries of what can be achieved in terms of efficiency, ease of use, and accuracy. This article delves into the latest trends and advancements in manual tile cutting technology, revealing how these innovations are transforming the landscape of tiling projects.

A notable trend in manual tile cutting is the development of lightweight, portable cutters. Traditionally, manual tile cutting tools were often heavy and cumbersome, making it challenging to transport them to different work sites or maneuver in tight spaces. Recent advancements, however, have focused on reducing the weight of manual tile cutting tools while retaining their durability and precision.

Manufacturers are increasingly using materials like aluminum and high-grade plastics in manual tile cutting machines, resulting in tools that are easy to carry without sacrificing quality. This portability is a major advantage for professionals and hobbyists who need to move between different locations. Additionally, these lightweight manual tile cutting tools often feature foldable designs, further adding to their convenience.

Precision is critical in manual tile cutting to achieve a clean, straight line, especially on more intricate tiling patterns. Innovations in manual tile cutting now focus on improving the accuracy of each cut. Many modern manual tile cutting machines incorporate enhanced guide systems, making it easier to control the cutting path.

One example of this is laser-guided manual tile cutting systems, which project a thin laser line onto the tile. This feature helps users visualize the cutting path more clearly, reducing the chances of error and ensuring a more accurate cut. Additionally, rulers and measuring tools on manual tile cutting machines have become more refined, often with easy-to-read markings and digital displays to allow for precise measurements before cutting.

Another innovative advancement in manual tile cutting is the addition of effort-saving mechanisms. In the past, the physical strength required to operate manual tile cutting tools was often a challenge for users, particularly when working with harder tile materials. Today’s manual tile cutting machines are equipped with advanced lever and gear systems, which reduce the amount of force needed to score and snap tiles.

Hydraulic-assisted systems, for instance, are becoming more common in manual tile cutting. These systems use hydraulic power to generate the pressure needed for cutting, minimizing the strain on the user. For DIY enthusiasts or those who undertake long hours of manual tile cutting, these effort-saving innovations make a significant difference in comfort and usability.

In today’s diverse tiling projects, manual tile cutting tools with multi-angle and multi-material cutting capabilities are gaining attention. Traditionally, manual tile cutting was largely limited to simple, straight cuts. However, with the rise of modern tile designs and materials, there is now a need for manual tile cutting machines that can handle a variety of angles and materials.

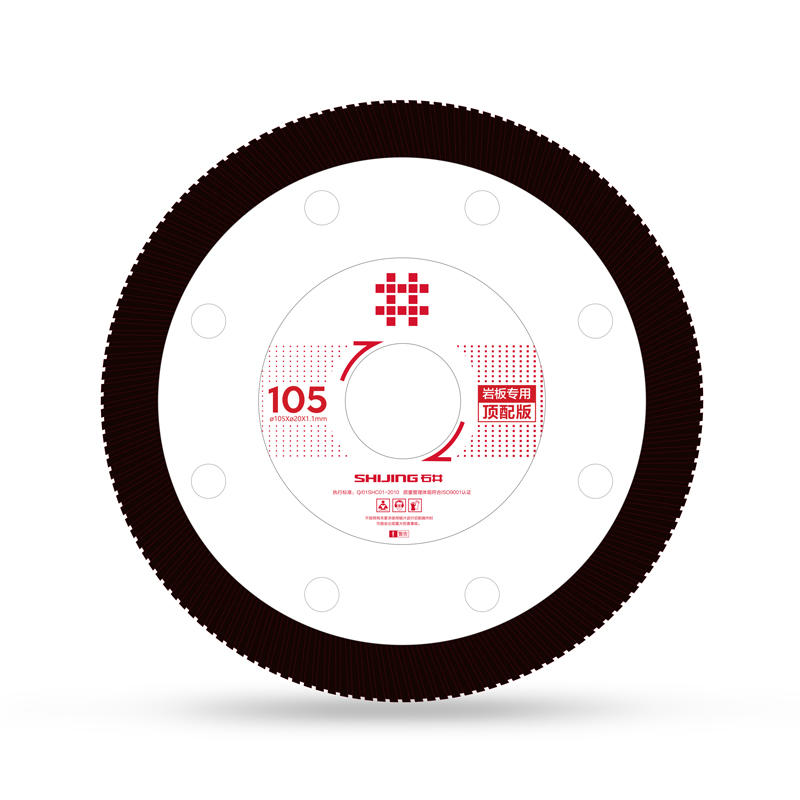

Advanced manual tile cutting tools now come with adjustable angle settings, allowing users to make cuts at various degrees. This feature is especially useful for intricate tile patterns and unique installations where straight lines alone won’t suffice. Additionally, many manual tile cutting tools are being designed to accommodate not only ceramic tiles but also harder materials like porcelain, glass, and even natural stone, broadening the range of tiling projects that can be completed with a single manual tile cutting tool.

Durability is a key consideration for professionals who rely on manual tile cutting tools daily. With the latest developments, manual tile cutting tools are now built to withstand the rigors of regular, heavy use. Improvements in blade quality and cutter mechanisms mean that these tools last longer and maintain their sharpness for an extended period.

Some manufacturers are now incorporating diamond-tipped blades and hardened steel materials in their manual tile cutting products, which significantly enhances the longevity of the blades. Additionally, anti-corrosion coatings and reinforced handles are features that further contribute to the durability of manual tile cutting tools, making them a sound investment for professionals.

Integrated Dust Management in Manual Tile Cutting

Dust is an inevitable byproduct of manual tile cutting, and it can pose a health risk as well as create a mess in the workspace. In response to this, some manufacturers are now integrating dust management systems into manual tile cutting tools. While traditional manual tile cutting does not typically produce as much dust as electric saws, these innovations still provide a cleaner, safer work environment.

Dust catchers or suction mechanisms can be attached to manual tile cutting tools, capturing the debris as it is produced. This feature is particularly beneficial for indoor projects, where dust can quickly spread and become a nuisance. Cleaner workspaces also contribute to a better view of the cutting line, enhancing precision in manual tile cutting.

In line with broader technological trends, digital enhancements are making their way into manual tile cutting. Digital displays and measurement systems are now commonly integrated into manual tile cutting tools, allowing for precise adjustments and consistent results. These features allow users to input measurements and align their tiles accurately, minimizing the risk of mistakes.

Some manual tile cutting tools also feature smart technology, such as pressure sensors that notify users if they are applying too much or too little force. These sensors help users optimize their cutting technique, prolonging the life of the tool and reducing the chances of tile breakage.

With ergonomics becoming a focus across industries, manual tile cutting tools have also seen improvements in design for user comfort. Handles and grips are now designed to reduce strain and fatigue, especially for those who use manual tile cutting tools for extended periods. Rubberized grips, padded handles, and adjustable stands are some of the features being incorporated to make manual tile cutting a more comfortable experience.

These ergonomic enhancements are not just about comfort but also contribute to safer manual tile cutting practices. A secure, comfortable grip allows for better control, reducing the risk of slipping and accidents. As more attention is placed on the user experience, manual tile cutting tools are evolving to support longer, more comfortable usage.

As advancements continue to emerge, the landscape of manual tile cutting is undoubtedly changing. With innovations focused on precision, ease of use, durability, and ergonomic design, manual tile cutting tools are becoming more sophisticated and user-friendly. These developments are making manual tile cutting more accessible to a wider audience, from seasoned professionals to DIY enthusiasts, expanding the range of projects that can be completed without resorting to electric cutters.

For anyone involved in tiling projects, these innovations in manual tile cutting offer exciting possibilities. From portable, lightweight designs to digital enhancements and multi-material capabilities, today’s manual tile cutting tools are more versatile and efficient than ever. As technology continues to evolve, manual tile cutting will likely see further refinements, bringing even more capabilities to those who rely on these tools in their tiling endeavors.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-3.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)