You can learn the recent information of Shijing.

In the ever-evolving landscape of construction and home renovation, mastering the art of tile cutting is essential for professionals and enthusiasts alike. With the advancement of technology, tile cutting equipment has undergone significant transformations, offering improved precision, efficiency, and safety. From manual tools to sophisticated machinery, the options available today empower craftsmen to elevate their skills and deliver exceptional results.

Traditional methods of tile cutting often involved manual scoring and snapping, a process that demanded skill and patience. While effective, it was time-consuming and prone to errors. However, with the advent of advanced tile cutting equipment, professionals now have access to a wide array of tools that streamline the cutting process and enhance productivity.

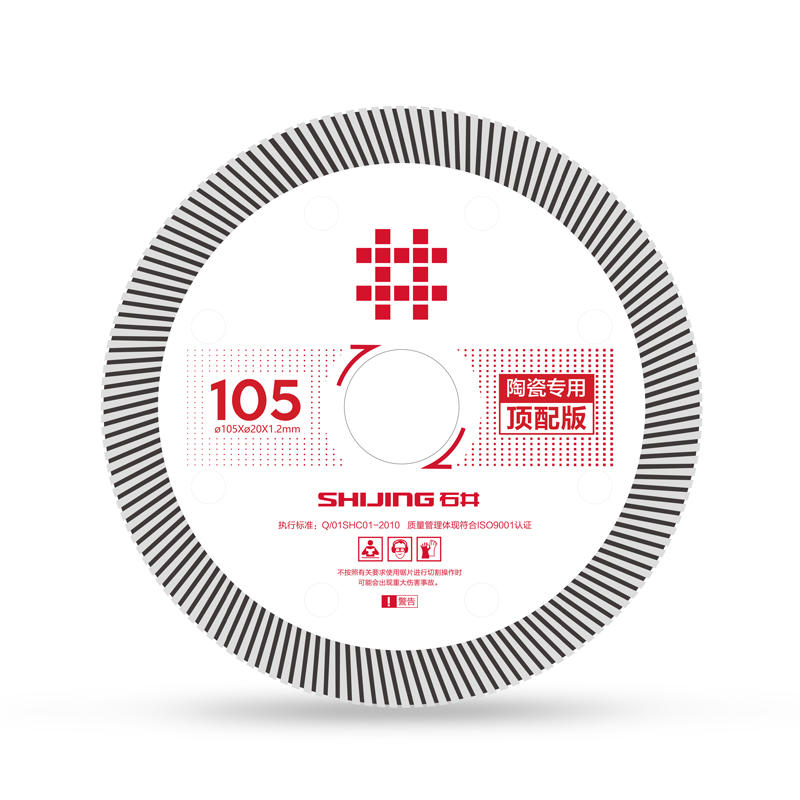

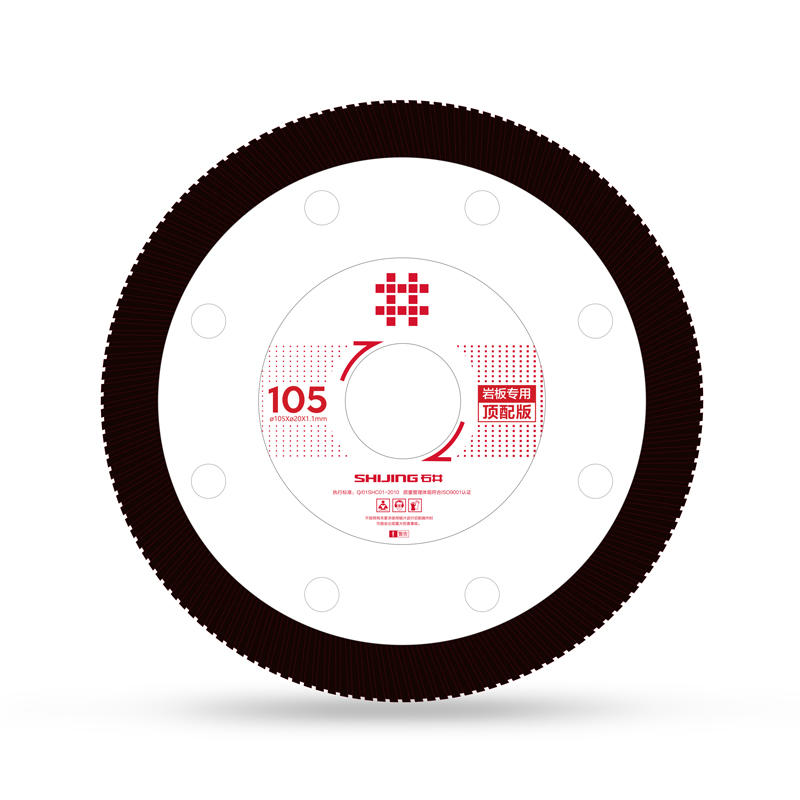

One of the notable innovations in tile cutting technology is the introduction of electric tile cutters. These machines utilize sharp blades or abrasive discs powered by electricity to effortlessly slice through tiles with precision and speed. Unlike manual methods, electric tile cutters eliminate the need for excessive force, reducing the risk of inaccuracies and fatigue among workers.

Among the various types of electric tile cutters available in the market, the tile cutter saw stands out as a popular choice among professionals. Equipped with a water-cooled diamond blade, tile cutter saws are designed to make clean and precise cuts through ceramic, porcelain, and even natural stone tiles. The incorporation of water cooling not only minimizes dust and debris but also prevents overheating, prolonging the lifespan of the blade.

Another noteworthy advancement in tile cutting technology is the development of laser-guided tile cutters. These innovative tools utilize laser beams to create precise cutting guidelines on the surface of the tile, enabling users to achieve accurate cuts with minimal effort. By eliminating guesswork and enhancing visibility, laser-guided tile cutters have revolutionized the way craftsmen approach intricate cutting tasks.

In addition to electric and laser-guided tile cutters, recent years have witnessed the rise of pneumatic tile cutting systems. Powered by compressed air, these cutting systems offer high-speed operation and unparalleled cutting accuracy. Ideal for large-scale projects and industrial applications, pneumatic tile cutters excel in handling heavy-duty materials and complex cutting patterns with ease.

While the emergence of advanced tile cutting equipment has undeniably transformed the industry, mastering these tools requires specialized training and expertise. Recognizing the importance of skill development, many manufacturers and industry associations offer comprehensive training programs and certification courses for aspiring tile craftsmen.

These training programs cover a wide range of topics, including equipment operation, safety protocols, and cutting techniques. Participants learn how to effectively utilize advanced tile cutting equipment to maximize efficiency while minimizing waste and errors. Additionally, hands-on workshops and demonstrations provide invaluable practical experience, allowing trainees to hone their skills under the guidance of experienced professionals.

Furthermore, advancements in digital technology have led to the development of computer-aided design (CAD) software tailored specifically for tile cutting. These sophisticated software solutions enable users to create intricate cutting patterns and designs with precision and ease. By leveraging CAD technology, craftsmen can bring their creative visions to life and deliver customized tile installations that exceed client expectations.

As the demand for high-quality tile installations continues to grow, professionals who possess advanced skills in tile cutting are in high demand. Whether it's precision cutting for intricate mosaic designs or seamless tile installations for large-scale projects, the ability to leverage advanced tile cutting equipment sets craftsmen apart in a competitive market.

Looking ahead, the future of tile cutting technology promises even more exciting innovations. From robotic tile cutting systems to augmented reality-assisted tools, the possibilities are endless. By embracing these advancements and investing in skill development, craftsmen can stay ahead of the curve and continue to deliver exceptional results in the ever-evolving world of construction and home renovation.

In conclusion, the evolution of tile cutting equipment has revolutionized the construction and home renovation industry, empowering professionals to enhance their skills and deliver unparalleled craftsmanship. From electric tile cutters to laser-guided systems, the options available today offer higher precision, efficiency, and safety. By investing in training and embracing technological advancements, craftsmen can position themselves for success in a competitive market driven by quality and innovation.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)