You can learn the recent information of Shijing.

-5.jpg)

In the world of industrial automation and material handling, the choice of gripping technology can make a significant difference in the efficiency, reliability, and versatility of a system. While traditional grippers have long been the go-to solution, vacuum suction cups are emerging as a compelling alternative, offering a range of unique advantages that are transforming the way we approach material handling tasks.

At the heart of the vacuum suction cup advance lies its ability to create a strong, uniform, and controlled grip on a wide variety of surfaces. Unlike traditional grippers, which rely on mechanical clamping or friction-based mechanisms, vacuum suction cups utilize the power of atmospheric pressure to securely hold objects in place. This approach provides several key benefits that set it apart from its counterparts.

One of the primary advantages of vacuum suction cups is their adaptability to different materials and surface types. Traditional grippers often struggle with delicate, porous, or irregularly shaped objects, as they may not be able to establish a secure grip without risking damage. Vacuum suction cups, on the other hand, can conform to the contours of the object, creating a tight seal for the safe handling of a diverse range of materials, including glass, plastic, metal, and even textiles.

This versatility is particularly valuable in industries such as electronics, packaging, and logistics, where the handling of fragile or sensitive items is a common challenge. Vacuum suction cups' ability to distribute the gripping force evenly across the surface of the object helps to minimize the risk of scratches, dents, or other forms of damage, ensuring the integrity of the products being handled.

Another significant advantage of vacuum suction is its ability to handle heavier loads with greater ease and precision. The suction force generated by the vacuum can be precisely controlled and adjusted to accommodate objects of varying weights, allowing for the efficient handling of a wide range of payloads. This flexibility is particularly beneficial in applications where the weight of the handled items may fluctuate, such as in the automotive industry or in the assembly of large-scale machinery.

Moreover, vacuum suction cups offer outstanding grip reliability compared to traditional grippers. The vacuum-based grip is not susceptible to the same limitations as mechanical clamping or friction-based systems, which can be affected by factors such as surface contamination, wear and tear, or changes in environmental conditions. Vacuum suction cups maintain a consistent and reliable grip, reducing the risk of dropped or mishandled items, and improving the overall safety and efficiency of the material handling process.

In addition to their adaptability and reliability, vacuum suction cups also offer significant advantages in terms of energy efficiency and operational costs. Traditional grippers often require complex and power-hungry actuation systems, such as hydraulic or pneumatic systems, to generate the necessary gripping force. Vacuum suction cups, on the other hand, can be operated using relatively simple and energy-efficient vacuum pumps, which can lead to significant cost savings in terms of both energy consumption and maintenance requirements.

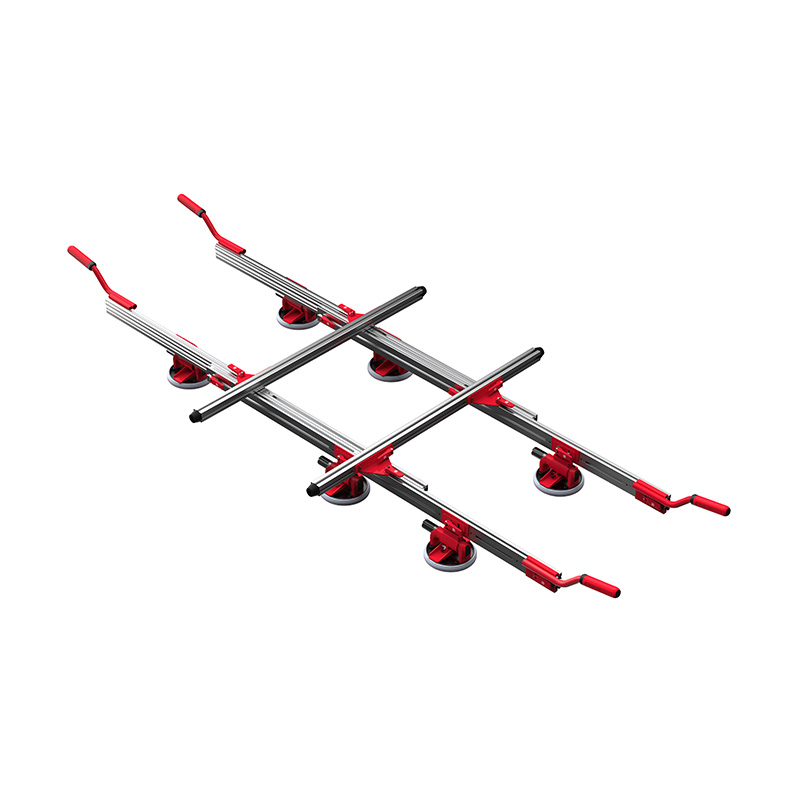

Furthermore, the compact and modular design of vacuum suction cups allows for greater flexibility in system integration and customization. These gripping devices can be easily configured and arranged in various patterns to accommodate different object sizes, shapes, and handling requirements, enabling manufacturers to optimize their material handling processes to suit their specific needs.

One of the exciting developments in the field of vacuum suction cups is the integration of advanced sensor technologies. By incorporating sensors that can monitor the vacuum levels, grip strength, and other critical parameters, vacuum suction cups can provide real-time feedback on the gripping process, allowing for enhanced control, error detection, and predictive maintenance capabilities. This integration of sensor technology further enhances the reliability and efficiency of vacuum suction cup-based material handling systems.

As the demand for more efficient, agile, and cost-effective material handling solutions continues to grow, the advantages of vacuum suction cups are becoming increasingly recognized across a wide range of industries. From the delicate handling of electronic components to the precise positioning of heavy machinery, these innovative gripping devices are revolutionizing the way we approach material handling tasks, offering a compelling alternative to traditional grippers.

In conclusion, vacuum suction cups offer a unique set of advantages that make them a highly compelling choice for material handling applications. Their adaptability to diverse surfaces, ability to handle heavier loads with precision, reliable grip, energy efficiency, and integration with advanced sensor technologies all contribute to their growing popularity in the industrial automation and material handling sectors. As the technology continues to evolve, the future of vacuum suction cups looks increasingly bright, with the potential to transform the way we approach material handling challenges across a wide range of industries.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

.jpg)

.jpg)

-2.jpg)

.jpg)

-3.jpg)

-4.jpg)

.jpg)

.jpg)