You can learn the recent information of Shijing.

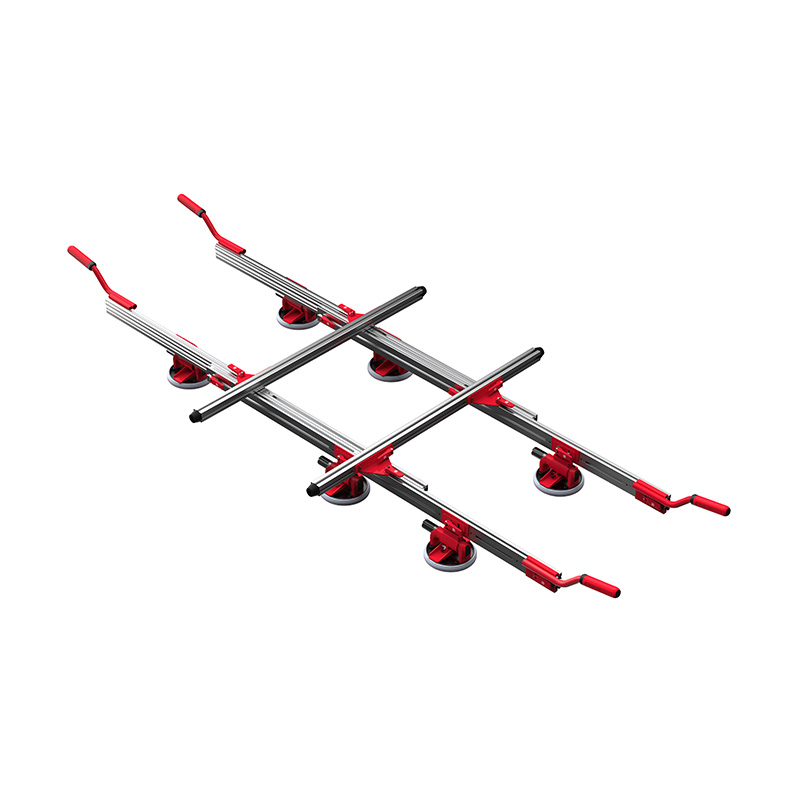

OEM heavy duty vacuum suction cups for lifting Company

In the manufacturing and industrial sectors, efficiency and precision are key elements in maintaining smooth operations and consistent production output. The heavy duty vacuum suction cup has emerged as a critical tool that not only enhances operational performance but also reduces wear and tear on mechanical components, minimizes operational errors, and increases overall productivity. In comparison to traditional mechanical clamps and fixtures, the heavy duty vacuum suction cup provides several advantages that can transform the way industries handle materials and automate processes. This article delves into how heavy duty vacuum suction cups address these critical issues in industrial settings.

One of the primary benefits of the heavy duty vacuum suction cup is its ability to significantly reduce wear and tear on mechanical components. In traditional systems, clamps and grippers often rely on physical contact and pressure to secure materials. Over time, this repeated contact leads to friction, which can cause deterioration of both the gripping components and the materials being handled. This type of wear is costly, not only because of the need to replace worn parts but also due to the potential downtime required for maintenance and repair.

The heavy duty vacuum suction cup, on the other hand, uses air pressure to hold materials in place, eliminating the need for physical clamping forces that cause friction. By adhering to surfaces using vacuum technology, the heavy duty vacuum suction cup reduces the stress on mechanical parts, extending their lifespan and reducing the frequency of repairs. The absence of direct contact ensures that delicate materials are handled with care, preventing surface damage and further wear, which is especially important in industries dealing with sensitive or fragile components.

In many industries, human error or mechanical misalignment can bring about operational issues such as misplacement of parts or improper handling, which can disrupt workflows and result in costly rework. Traditional clamping mechanisms can sometimes require manual adjustment or involve complex processes that increase the chance of errors. These errors not only waste materials but also slow down production, affecting overall efficiency.

The heavy duty vacuum suction cup minimizes such errors by providing a more reliable and automatic method of securing materials. Once activated, the heavy duty vacuum suction cup ensures consistent positioning, eliminating the need for manual intervention. The simplicity of vacuum-based systems also means that operators are less likely to encounter complex setup issues, reducing the likelihood of mistakes. As a result, the heavy duty vacuum suction cup helps streamline operations by providing a more straightforward and effective method of holding materials securely during production processes.

In automated systems, the heavy duty vacuum suction cup plays a critical role in robotic and automated material handling. Unlike traditional clamps that may require realignment or recalibration, the heavy duty vacuum suction cup ensures consistent performance, reducing the need for frequent adjustments. This consistency is particularly valuable in high-speed production lines, where precision and timing are essential to maintaining throughput. By eliminating human error and providing a more reliable system, the heavy duty vacuum suction cup contributes to smoother operations and fewer disruptions in production.

The introduction of heavy duty vacuum suction cups into industrial processes can bring about significant productivity gains. Traditional clamping systems, while effective in some applications, often require manual setup, adjustments, and maintenance. These additional steps take time and reduce overall efficiency. In contrast, the heavy duty vacuum suction cup offers a faster, more efficient solution that allows for quicker setup and smoother operation.

In industries where speed and precision are vital, the heavy duty vacuum suction cup enables faster transitions between tasks. The quick-release function of the heavy duty vacuum suction cup means that materials can be handled more swiftly, reducing idle time and allowing operators to focus on other tasks. Additionally, the automation capabilities of the heavy duty vacuum suction cup further enhance productivity by allowing for seamless integration into robotic systems and high-speed production lines. The suction cup's ability to quickly attach to and release materials makes it an ideal solution for industries that require rapid material handling, such as automotive manufacturing, packaging, and electronics.

Another factor contributing to increased productivity is the ability of the heavy duty vacuum suction cup to handle a wide variety of materials and shapes. Traditional clamps often require specialized setups for different components, which can slow down operations as parts are swapped out or adjusted. In contrast, the heavy duty vacuum suction cup is versatile enough to handle different surfaces, including smooth, rough, or uneven materials. This versatility makes the heavy duty vacuum suction cup a more flexible and adaptable solution for industries that deal with a range of products or materials in their production processes.

The heavy duty vacuum suction cup has become a transformative tool in various industrial applications, offering clear advantages over traditional mechanical clamps and fixtures. By reducing wear and tear on mechanical parts, minimizing operational errors, and significantly increasing productivity, the heavy duty vacuum suction cup plays a crucial role in modern manufacturing and material handling. Its ability to provide consistent, reliable, and efficient performance makes it a valuable addition to any production line, particularly in industries where speed, precision, and reliability are essential.

In comparison to traditional methods, the heavy duty vacuum suction cup offers a less invasive and more efficient alternative, extending the life of equipment and reducing maintenance needs. Furthermore, by preventing operational errors and optimizing workflow processes, the heavy duty vacuum suction cup ensures that production lines run smoothly and efficiently, bringing about higher throughput and reduced costs.

As industries continue to evolve and automation becomes increasingly prevalent, the heavy duty vacuum suction cup will likely play an even more critical role in enhancing productivity and reducing operational challenges. Its versatility, ease of use, and ability to integrate with modern automated systems make the heavy duty vacuum suction cup a key component in the drive toward more efficient and streamlined industrial processes. Whether in automotive manufacturing, electronics, packaging, or other sectors, the heavy duty vacuum suction cup is a tool that will continue to drive innovation and success in material handling and production.

English

English 中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch

.jpg)

-2.jpg)

.jpg)

.jpg)